WARNING-DAMAGE CAN OCCUR TO YOU AND ENGINE BY DOING THIS MOD

Okay, I have made a STEP by STEP tutorial for removing the governor on a 5hp FLAT HEAD Briggs engine.

This Tutorial Starts off assuming you have removed any linkage from the carburetor to the governor arm.

AND/OR have eliminated the Governor/throttle Plate.

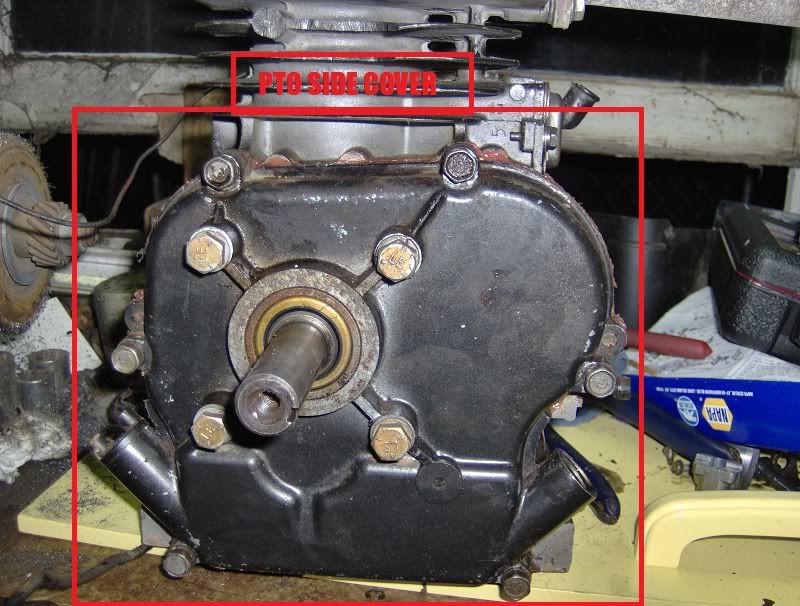

TOTAL COST FREE

TOOLS NEEDED

7/16" wrench

3/8" wrench

Hammer (If needed)

Needle Nose Pliers

Bench Grinder (or other cutting device)

Materials

Oil Container (Tupperware works great)

PTO Gasket (can be made from cereal box, check end play after installed)

-------------------------------------------------------------

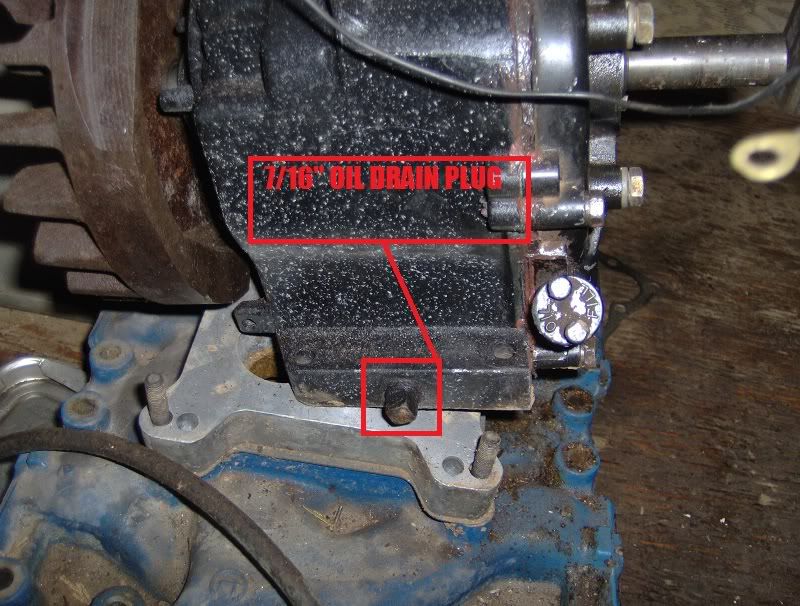

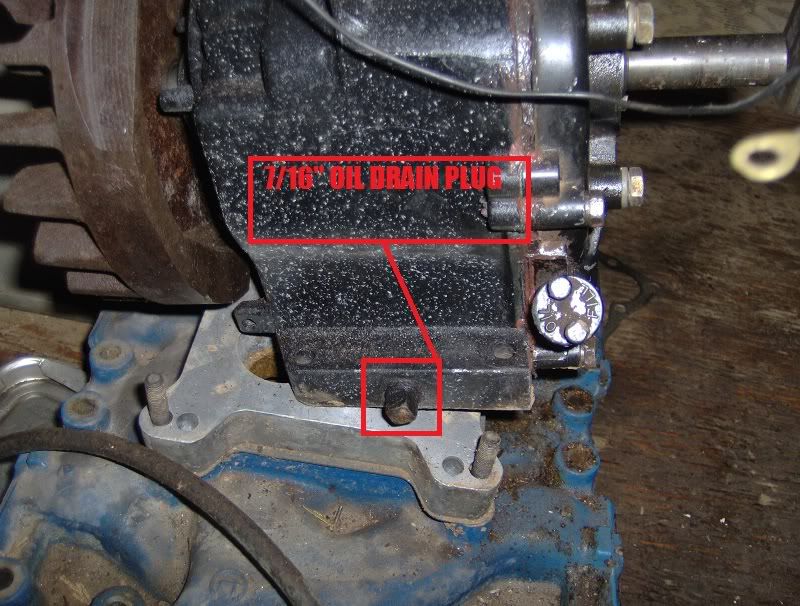

STEP 1: Remove OIL Drain Plug with 7/16 " wrench, and Drain OIL!

STEP 2: Remove Governor Arm Bolt with 3/8" wrench and remove governor arm.

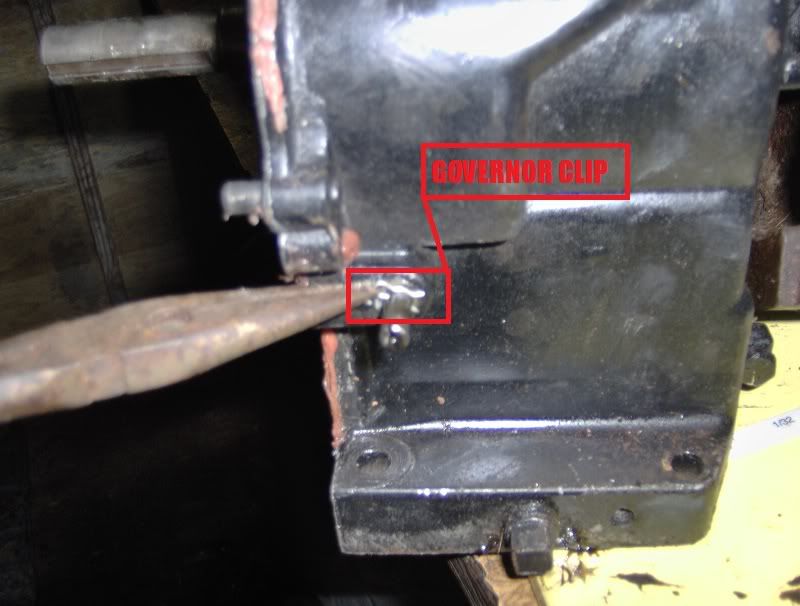

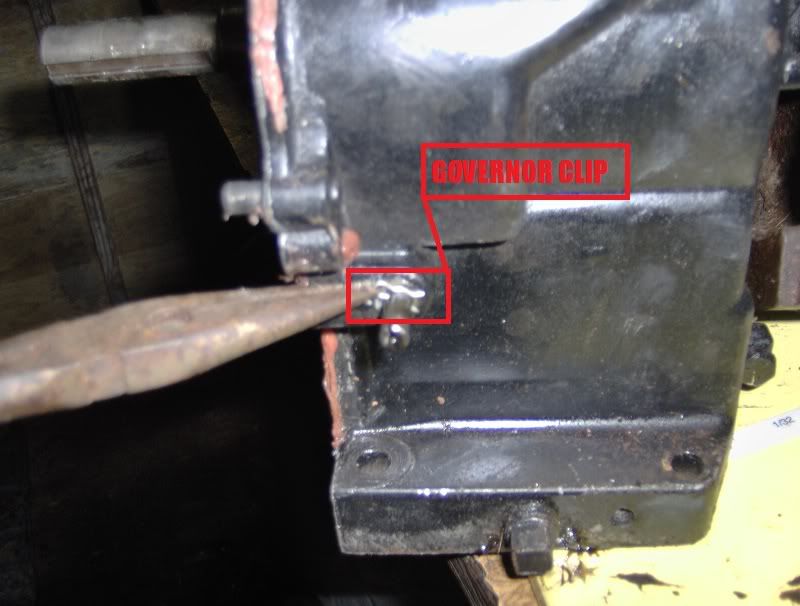

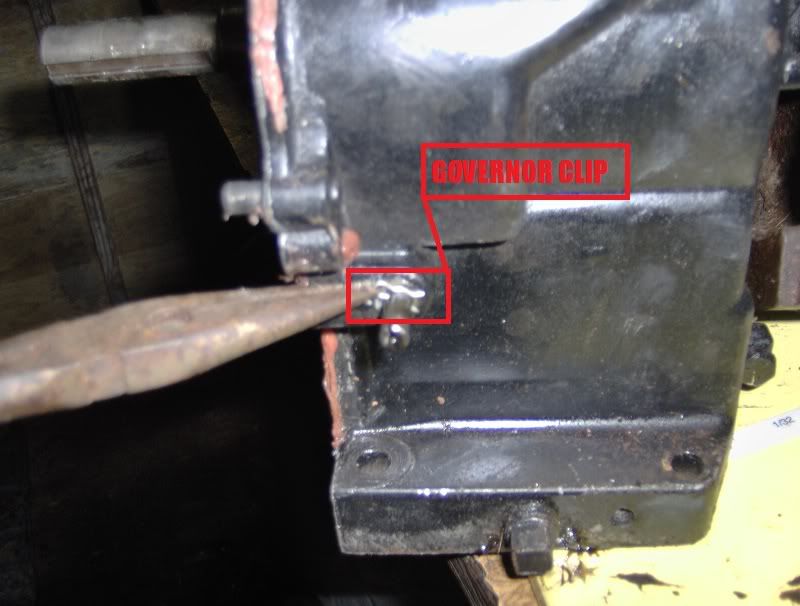

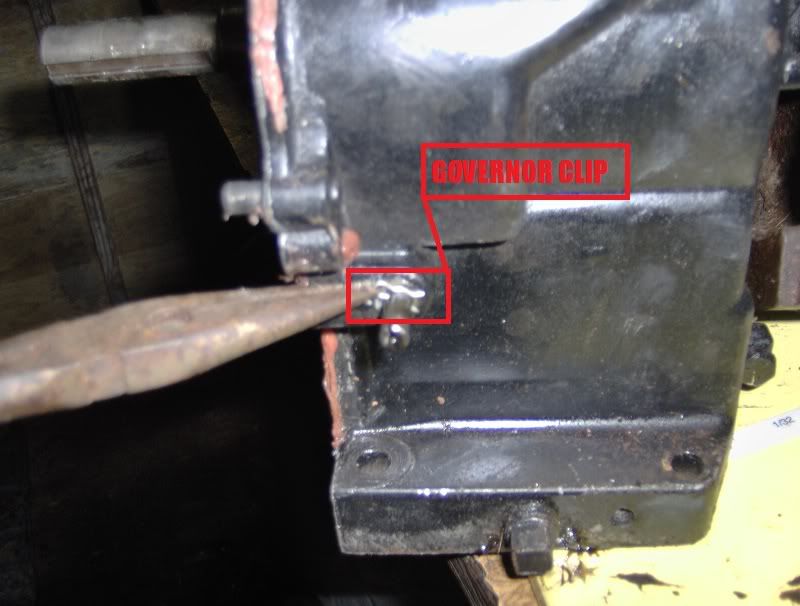

STEP 3: Remove Governor Clip and Washer (if washer is there)

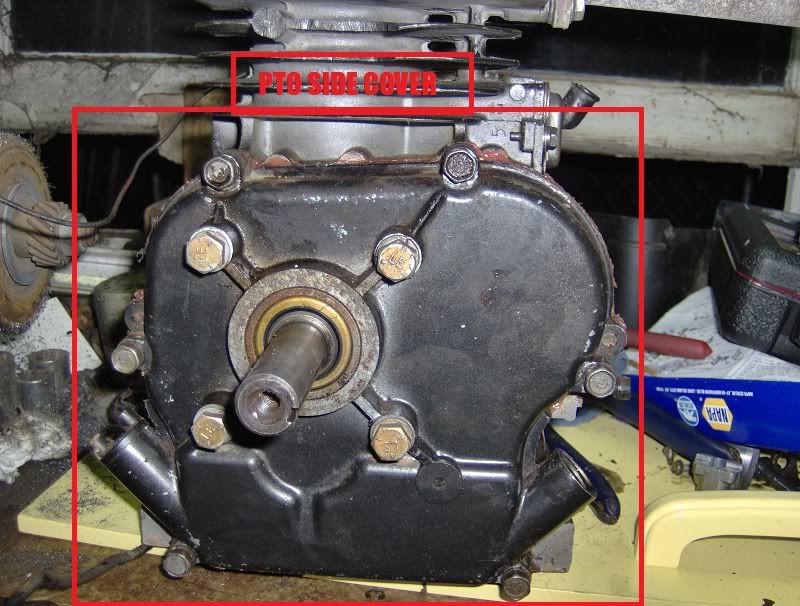

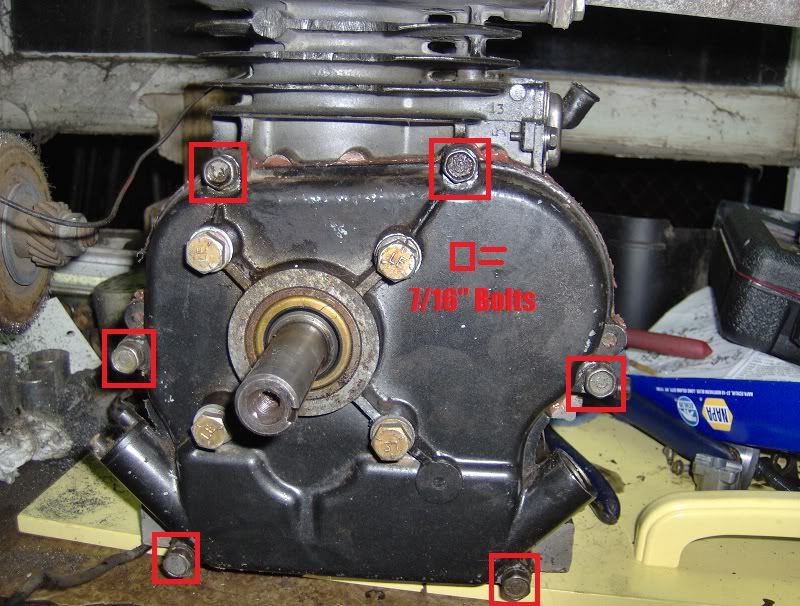

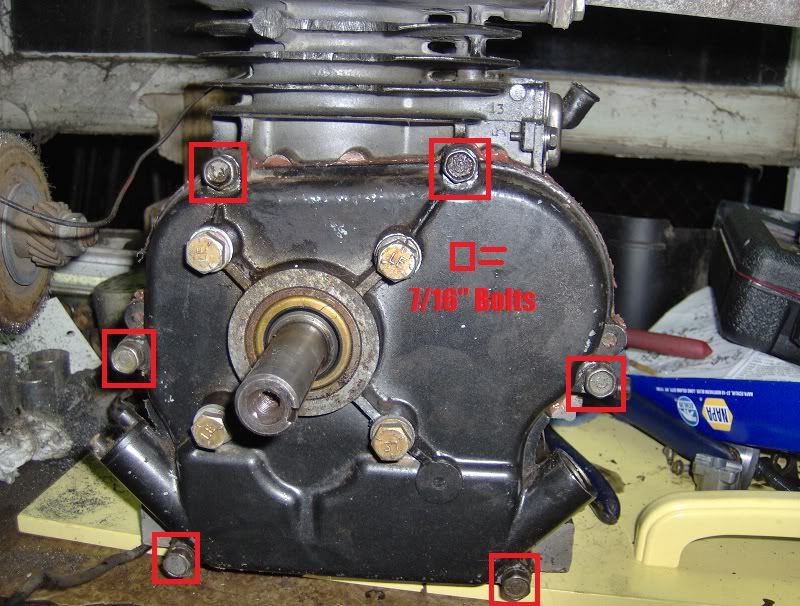

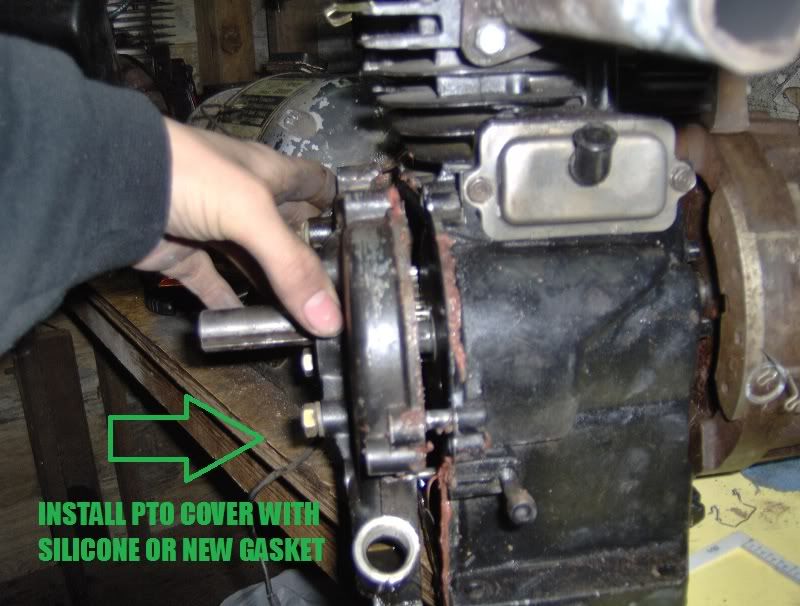

STEP 4: Remove ALL 6 PTO side cover bolts with 7/16" wrench.

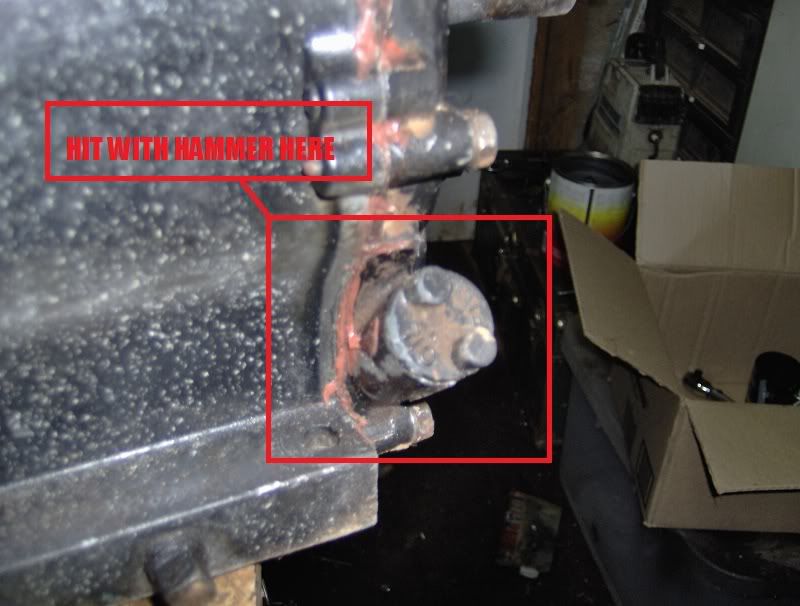

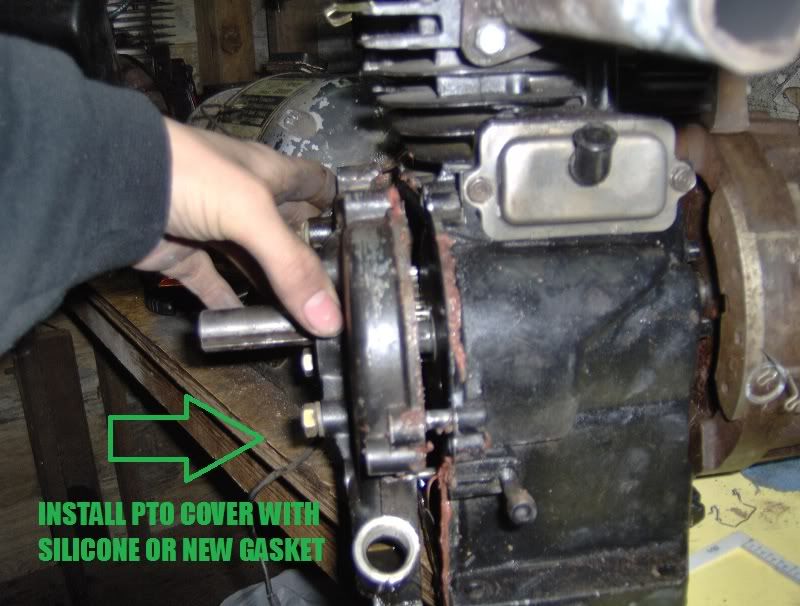

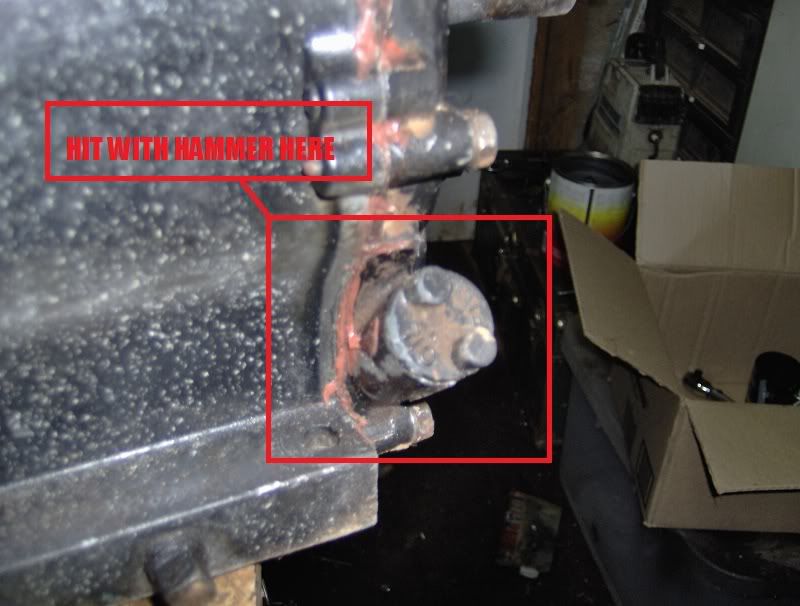

STEP 5: Extract PTO side Cover with hands,ONLY USE A HAMMER in the Spot shown below if it won't budge, be careful, you can break PTO Side cover.

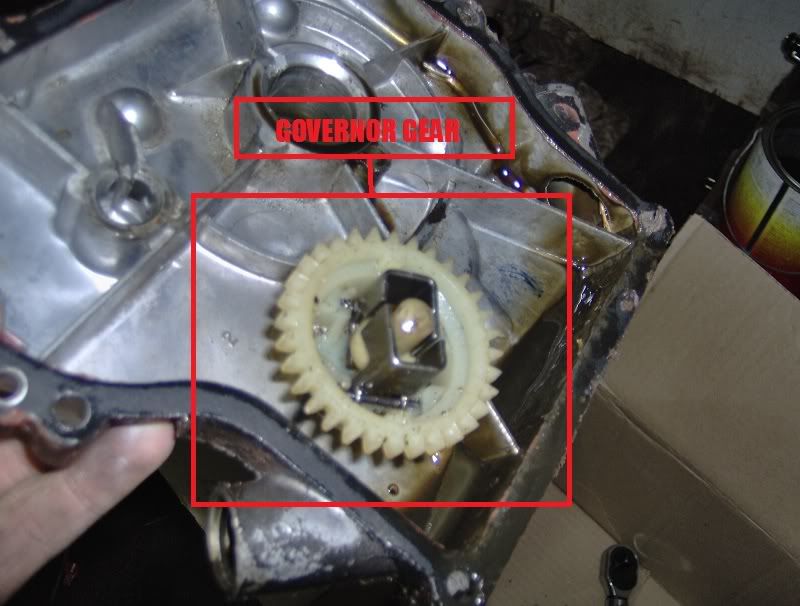

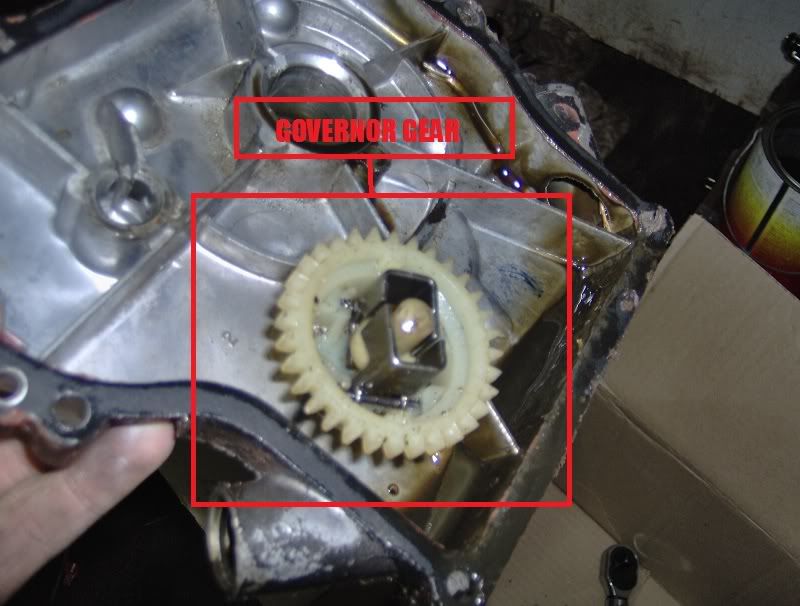

STEP 6: This is the Governor Gear, remove it with pliers.

STEP 7: Remove this WASHER!it is directly behind the governor gear!

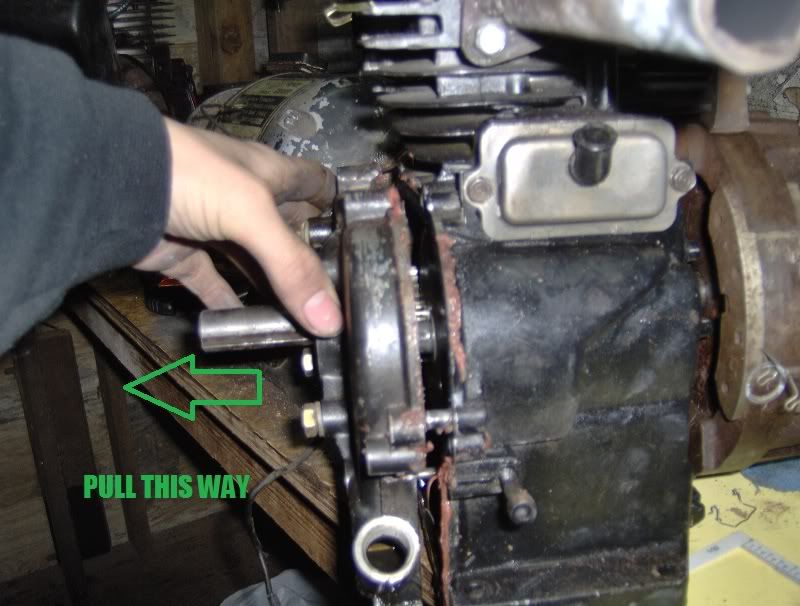

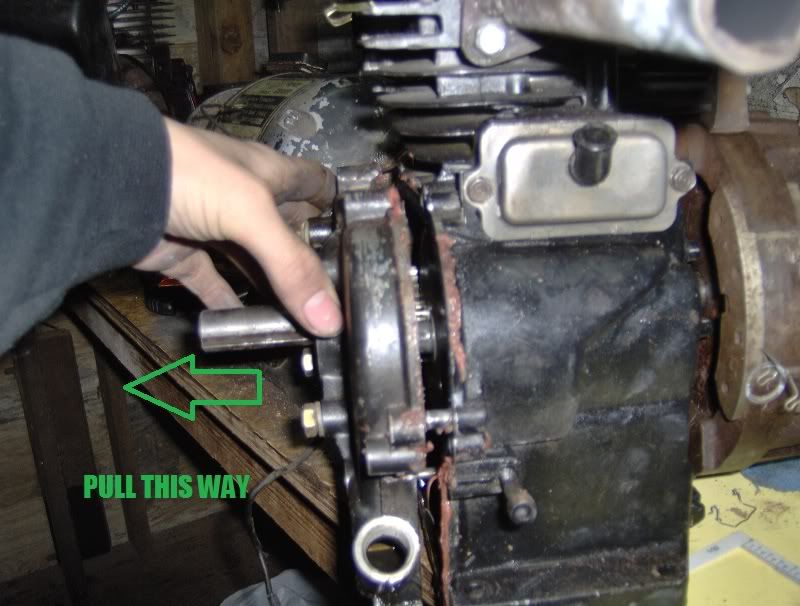

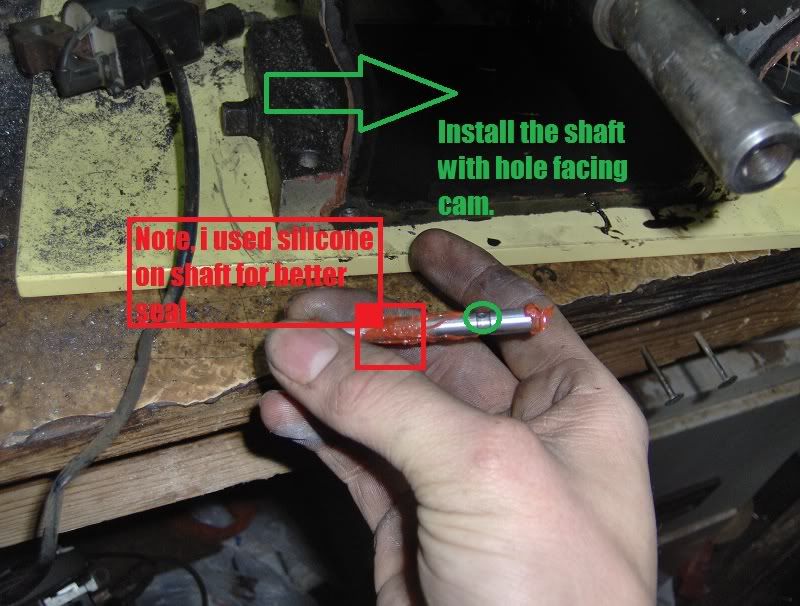

STEP 8: This is the Governor Shaft,what you see me grabbing is the 'flap" on the shaft. Pull it towards Crankshaft

STEP 9: Use Bench grinder or "another cutting device" to remove the "flap" from the governor shaft

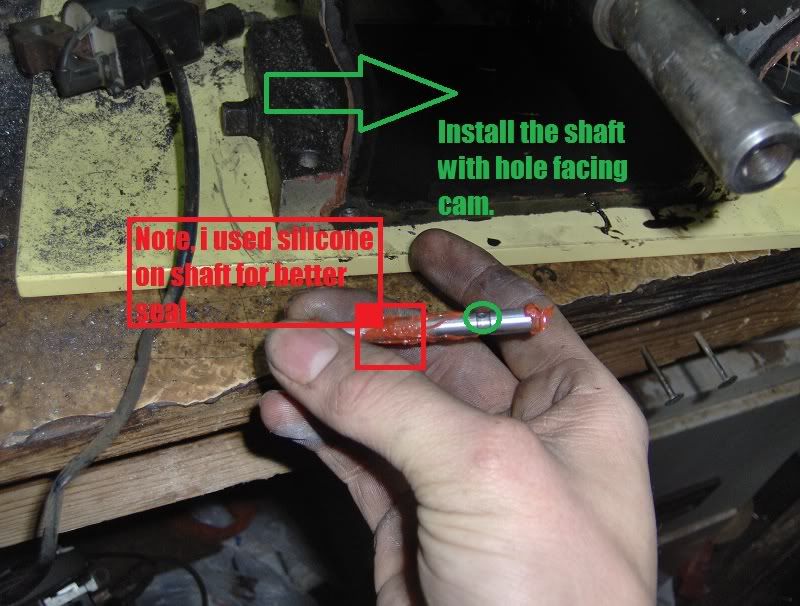

STEP 10: Reinstall the Governor shaft. (OPTIONAL ->) You can lube it if you wish.

STEP 11: reinstall Governor Clip

STEP 12: Reinstall PTO side cover with new gasket, and torque bolts to 15lbs or until "SNUG"

THAT'S IT YOUR DONE! YOU DO NOT NEED THE GOVERNOR ARM! NOW HOOK YOUR THROTTLE UP DIRECTLY TO CARBURETOR! AND !!ADD!! OIL

Written by Solomon

STICKY ANYONE???

Okay, I have made a STEP by STEP tutorial for removing the governor on a 5hp FLAT HEAD Briggs engine.

This Tutorial Starts off assuming you have removed any linkage from the carburetor to the governor arm.

AND/OR have eliminated the Governor/throttle Plate.

TOTAL COST FREE

TOOLS NEEDED

7/16" wrench

3/8" wrench

Hammer (If needed)

Needle Nose Pliers

Bench Grinder (or other cutting device)

Materials

Oil Container (Tupperware works great)

PTO Gasket (can be made from cereal box, check end play after installed)

-------------------------------------------------------------

STEP 1: Remove OIL Drain Plug with 7/16 " wrench, and Drain OIL!

STEP 2: Remove Governor Arm Bolt with 3/8" wrench and remove governor arm.

STEP 3: Remove Governor Clip and Washer (if washer is there)

STEP 4: Remove ALL 6 PTO side cover bolts with 7/16" wrench.

STEP 5: Extract PTO side Cover with hands,ONLY USE A HAMMER in the Spot shown below if it won't budge, be careful, you can break PTO Side cover.

STEP 6: This is the Governor Gear, remove it with pliers.

STEP 7: Remove this WASHER!it is directly behind the governor gear!

STEP 8: This is the Governor Shaft,what you see me grabbing is the 'flap" on the shaft. Pull it towards Crankshaft

STEP 9: Use Bench grinder or "another cutting device" to remove the "flap" from the governor shaft

STEP 10: Reinstall the Governor shaft. (OPTIONAL ->) You can lube it if you wish.

STEP 11: reinstall Governor Clip

STEP 12: Reinstall PTO side cover with new gasket, and torque bolts to 15lbs or until "SNUG"

THAT'S IT YOUR DONE! YOU DO NOT NEED THE GOVERNOR ARM! NOW HOOK YOUR THROTTLE UP DIRECTLY TO CARBURETOR! AND !!ADD!! OIL

Written by Solomon

STICKY ANYONE???