panchothedog

Well-known member

- Messages

- 1,450

- Reaction score

- 1,996

You don't need 20 horsepower to go very fast in a go kart. And you don't need a

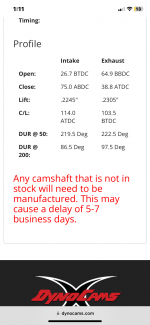

.356" lift cam any more than a 28mm carburetor. Do you even know what coil bind is? A stock cam with some ratio rockers and 26 lb springs will deliver good performance, especially with increased compression as I explained in my 1st post. Have you even ever taken one apart? Do you own piston ring compressor.

How about a valve spring compressor. You will also need a 1/2" drive torque wrench, and a 1/4" torque wrench calibrated in inch pounds. If you don't have these tools, you won't get to 1st base in trying to build an engine. I am not a professional engine builder. Just an old man who has been working on and racing different things for more than 50 years, and have built about 8 Predators in the last 4 years. It is VERY easy for me to recognize from your post that you are way too fixated on big this and big that. Buy your engine, get.the aftermarket rod and flywheel, delete the governor, put some stiffer valve springs, jet the stock carburetor and put on a pipe and rvl muffler. Mount it on your kart and drive the darn thing. You will then have the foundation to modify more extensively from there going forward.

.356" lift cam any more than a 28mm carburetor. Do you even know what coil bind is? A stock cam with some ratio rockers and 26 lb springs will deliver good performance, especially with increased compression as I explained in my 1st post. Have you even ever taken one apart? Do you own piston ring compressor.

How about a valve spring compressor. You will also need a 1/2" drive torque wrench, and a 1/4" torque wrench calibrated in inch pounds. If you don't have these tools, you won't get to 1st base in trying to build an engine. I am not a professional engine builder. Just an old man who has been working on and racing different things for more than 50 years, and have built about 8 Predators in the last 4 years. It is VERY easy for me to recognize from your post that you are way too fixated on big this and big that. Buy your engine, get.the aftermarket rod and flywheel, delete the governor, put some stiffer valve springs, jet the stock carburetor and put on a pipe and rvl muffler. Mount it on your kart and drive the darn thing. You will then have the foundation to modify more extensively from there going forward.